High Quality Overhead Crane Malaysia

Overhead Crane Manufacturer

POWERTECHNIC is a licensed crane manufacturer/specialist. Our crane equipped with Europe hoists, branded electrical components and designed with extra safety factor to optimize safety & work efficiency.

- Gantry Crane

- Jib Crane

- Overhead Crane

- Underhung Crane

- Wall Crane

- Chain Hoist

- Monorail Hoist

- Wire Rope Hoist

An overhead crane is a crucial piece of equipment for factories and industrial facilities, providing efficient material handling solutions that improve workflow and safety. These cranes are designed to lift and transport heavy loads across large areas, making them essential for optimizing production processes. By incorporating overhead cranes, factory owners can reduce manual labor, minimize downtime, and enhance overall productivity, ultimately leading to significant cost savings.

As a reputable overhead crane supplier in Malaysia, POWERTECHNIC offers high-quality overhead crane systems. Their team of experts specializes in delivering professional installations tailored to each business’s unique needs. With their extensive experience, they ensure that every installation meets the highest performance and safety standards. For factory owners seeking to streamline operations and enhance efficiency, POWERTECHNIC offers reliable overhead crane solutions that deliver long-term value and support business growth.

Product Features

- Designed with extra safety factor

- Low dead weight and high rigidity

- Maximum deflection: < 1/750mm of the Span

- Cross and long travel safety protection

- Precise manoeuvre; Double speed for soft start and soft stop

- Revolving light and buzzers for additional safety

- Anti-collision sensors for multiple cranes within a bay

- Suspended, mobile or wireless control options

- Industrial premium coating (1 layer primer and 2 layer finishing)

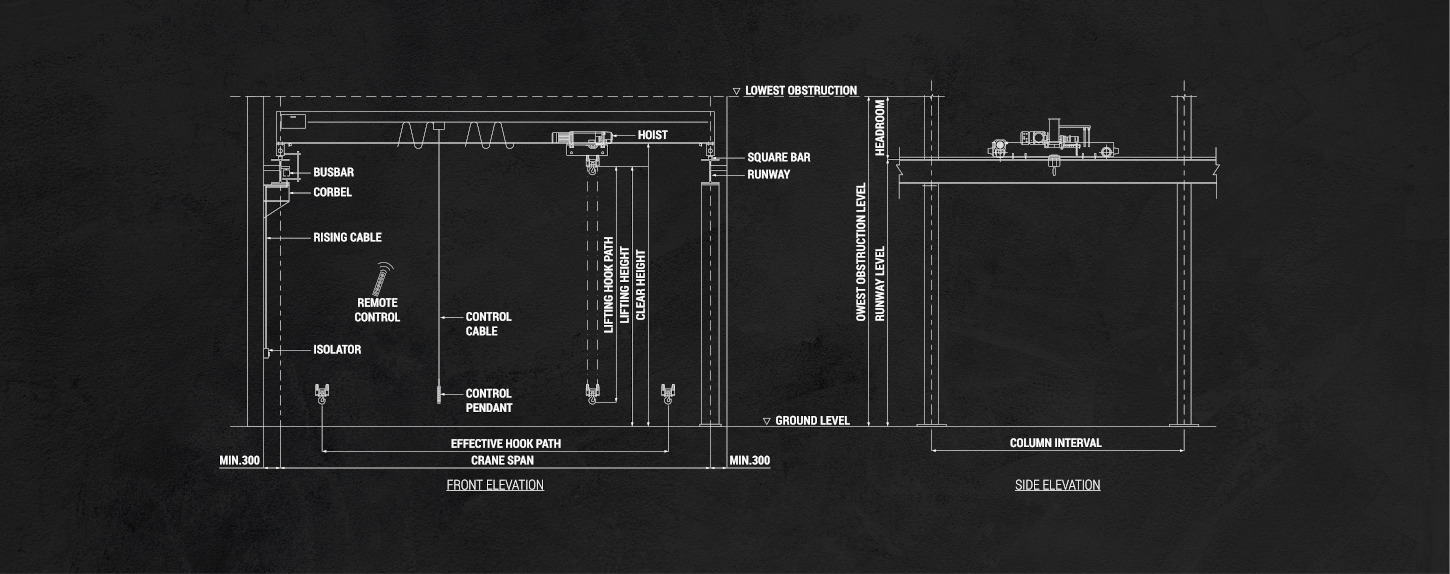

Technical Specification

- Safe Working Load: 500kg – 500 tonnes

- Span: 3m – 50m

- Lifting Height: 3m – 100m

- Hoist Type: European Standard Electrical Wire Rope Hoist/Chain Hoist

- Hoist Motor Duty: FEM 2m – FEM 4m

- Control Voltage: 48 volts

- Hoisting Speed: 4 / 1.3 m/min

- Cross Travel Speed: 20 / 5 m/min

- Long Travel Speed: 3 – 30 m/min

Our crane project incorporates hoist products from Europe Standard Hoisting Mechanism, which are CE-marked to confirm compliance with the Machinery Directive 2006/42/EC. This directive establishes the regulatory foundation for health and safety standards across the European Union.

- Compliance with Machinery Directive 2006/42/EC

- Thermal protection and Water resistant : IP 54

- Self-lubricating Gear Box

- Self-Braking Lifting Motor

- Overload Protection System

- High Tensile Wire Rope

- Wire Rope Guide

- Hoisting Limit Switch

Our crane project incorporates hoist products from Europe Standard Hoisting Mechanism, which are CE-marked to confirm compliance with the Machinery Directive 2006/42/EC. This directive establishes the regulatory foundation for health and safety standards across the European Union.

TYPE OF CRANE

UNDERHUNG CRANE

Underhung Crane design is having same operation mode with Overhead Crane, the only main concept is to suspend the completed crane units onto the available Building-Beams or Steel-Beams to create more available working space (Column-less). Practically, 500kg to 2000kg in Safe Working Load are being applied in industrial process-lines.

GANTRY CRANE

Gantry Cranes are operated independently on its own support Main-Leg and Auxiliary-Leg. The runway rails are rest on floor level which could allow the Crane units to be applied commonly at outdoor or indoor area without affecting the building structure. Sometime, the design could be in Semi-Gantry Crane form, whereby only the Auxiliary-Leg will be running on floor level, the other long travel components will be running on designed runway beams at higher level.

JIB CRANE

Jib Cranes are available in the form of “independent Column-Mounted” or “Wall-Mounted”. The Jib Arm could be slewing in designed angle (90 degree to 360 degree) to cover the working area radius required. Applicable to small working section with high frequency in lifting process. Practically, Safe Working Load or 500kg to 2000kg are generally applied.

WALL CRANE

Wall Cranes are installed to travel along the building wall with the support or runway beams. Generally, this crane design is applied to support heavy lifting usage in machining or second processing line, whereby the main building overhead crane on top of it are not able to fully support. As supporting crane, the SWL are usually in the form or 500kg to 2000kg.

MONORAIL HOIST

Mostly applied to facilitated the transforming of goods or items from Point-A to Pointed-B which could be reached in-line. Curved Monorail Hoist are available to suit the served points required which one not in a single straight line. Retractable Monorail Hoist are designed to retract-in the main monorail beam, mainly to reserve the way for the closing of building access doors.

WIRE ROPE HOIST

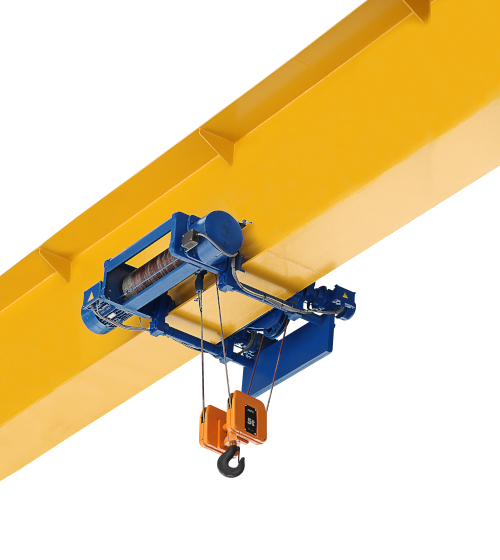

LOW HEADROOM HOIST

Most frequently used with single girder bridge cranes. Compact construction with maximum utilisation of space.

STANDARD FEATURES

- Capacity: from 0.8 to 50 tonnes

- Duty mode (FEM): from 1 Am to 3 m

- Reeving: 2/1, 4/1

- Lifting speed: V1 and V2

- Lifting height: from 7 to 32 m

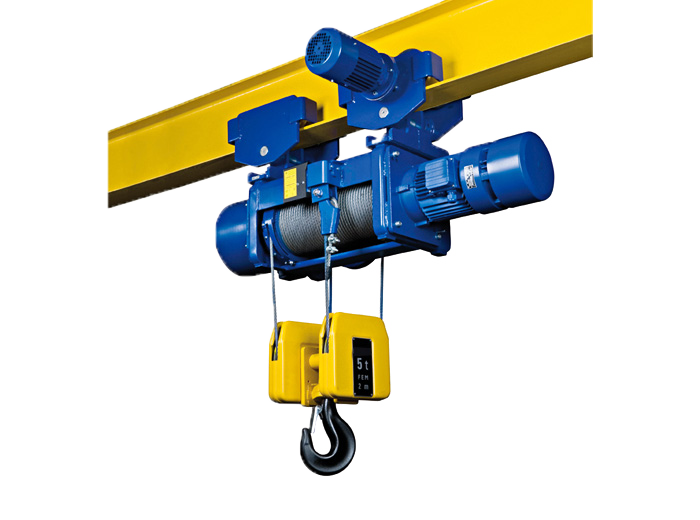

NORMAL HEADROOM HOIST

Mounted to single girder cranes when there are no specific requirements about lifting heights.

STANDARD FEATURES

- Capacity: from 0.8 to 50 tonnes

- Duty mode (FEM): from 1 Am to 3 m

- Reeving: 2/1, 4/1

- Lifting speed: V1 and V2

- Lifting height: from 7 to 32 m

STATIONARY HOIST

For crane manufacturers producing crane trolleys and for some custom-made solutions.

STANDARD FEATURES

- Capacity: from 0.8 to 50 tonnes

- Duty mode (FEM): from 1 Am to 3 m

- Reeving: 2/1, 4/1

- Lifting speed: V1 and V2

- Lifting height: from 7 to 32 m

DOUBLE RAIL HOIST

Double rail crane trolley with foot mounted wire rope hoist. Solution for double girder bridge cranes with heavy loads.

STANDARD FEATURES

- Travel speed (m/min): 20/5, 15/3.8

- Capacity: up to 16 tonnes

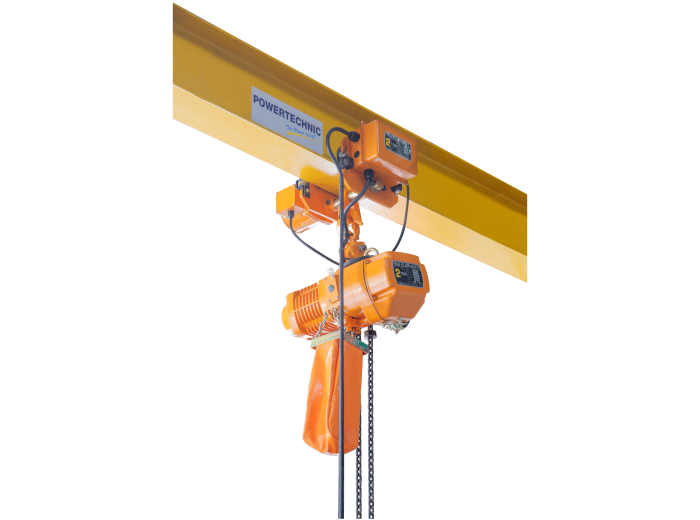

CHAIN HOIST

ELECTRICAL CHAIN HOIST

Flexible and durable electrical chain hoist, ideal lifting device for loads not more than 2 ton.

STANDARD FEATURES

- Capacity: 0.5 – 2 tonnes

- Lifting Speed: Single / Double speed

- Lifting height: 5 m (or upon request)

- Trolley: Motorized, plain, or gear trolley

Get your overhead crane Malaysia with us today!

Ready to enhance your factory’s efficiency with premium-built equipment? POWERTECHNIC is your go-to provider of overhead cranes in Malaysia. Contact our expert team today for reliable solutions that meet your business needs. Click the button now to get started!

Top Overhead Crane Solutions in Malaysia for Industrial Lifting Equipment

Overhead cranes are essential for lifting and transporting heavy loads in industrial environments. These systems are a mainstay in manufacturing, warehousing, logistics, and construction, where efficient material handling is crucial for productivity and safety. In Malaysia, the demand for reliable overhead crane solutions continues to grow as industries modernise their operations and prioritise workplace safety.

Read More Close

POWERTECHNIC is a trusted local supplier and manufacturer of industrial lifting equipment, offering a full range of overhead crane systems tailored to Malaysian businesses. With over 20 years of experience, we deliver high-performance, safety-compliant solutions.

Electric Overhead Crane and Hoist Options

Overhead crane systems are available in several configurations to suit different applications. Common types include:

- Single Girder Cranes: Ideal for lighter loads and limited spaces. Economical and suitable for most workshops and warehouses.

- Double Girder Cranes: Designed for heavier loads and longer spans, offering higher hook height and better load stability.

- Top-Running Cranes: Run on rails mounted on top of runway beams; best for high-capacity operations.

- Under-Running Cranes: Suspended from the building structure, suited for lighter loads and buildings with limited headroom.

While manual systems exist, most industrial applications in Malaysia now use electric overhead cranes for greater efficiency and performance. These cranes can be equipped with wire rope hoists for heavy-duty lifting or electric chain hoists for lighter, repetitive tasks—each tailored to specific load, speed, and safety requirements.

Custom-Made Bridge Cranes for Warehouse and Heavy-Duty Applications

Every industrial environment has unique needs, which is why POWERTECHNIC offers custom-made bridge cranes. From load capacity and span to lifting height and speed controls, each specification is engineered for optimal performance.

These bespoke crane systems are especially suited for:

- Heavy-duty production lines where consistent, high-capacity lifting is required.

- Warehouse and distribution centres where space and storage height are critical factors.

- Logistics and freight operations demand reliable material movement and handling.

Customisation ensures that each overhead crane system not only meets operational needs but also complies with relevant safety and regulatory standards.

Best Overhead Crane Systems for Industrial Needs

The best overhead crane systems are defined by their reliability, compliance with international standards, and ability to be tailored to specific industrial needs. Leading suppliers like POWERTECHNIC provide end-to-end services for every project stage:

- Engineering consultation and site assessment

- Customised design and system specification

- Local fabrication and manufacturing

- On-site installation and testing

With over 20 years of industry experience, POWERTECHNIC is a recognised name in Malaysia’s industrial lifting market, backed by certifications, skilled technicians, and a strong portfolio of successful crane installations.

Looking to upgrade your lifting systems? Contact us today to explore our complete range of overhead crane solutions that are built for your industry, tailored for your operations.

FAQs about POWERTECHNIC Overhead Crane

What types of overhead cranes are available for sale?

We offer a wide range of overhead cranes for sale in Malaysia, including single girder, double girder, top-running, and under-running cranes. Each type is designed to meet different industrial needs based on load capacity, span, and specific operational requirements.

Based on your specific needs, we can provide overhead cranes that are suitable for manufacturing plants, fabrication facilities, warehouses, and workshops.

What lifting capacities and specifications can be supported?

Our overhead cranes can support lifting capacities up to 500 tonnes. The exact specifications for each crane are determined by several key parameters, including the runway interval (the distance between supporting columns), the bridge span (distance between parallel runways), safe working load requirements, required lifting height, and the desired hoisting and trolley speeds—ensuring the system meets both operational needs and safety standards.

What components are included in the overhead crane system?

Each of our overhead crane systems is integrated with essential components, including the hoist equipment, control systems, electrical components, bridge drive, trolley drive, as well as safety features. Additionally, accessories such as hooks, slings, and attachments are also provided.

What safety standards do the overhead cranes comply with?

We design and construct our overhead cranes in compliance with British Standards, BS 2573-1 and BS 466. These standards set out comprehensive criteria for design requirements, operational safety, and fabrication processes.

In addition to meeting international standards, our cranes are JKKP/DOSH (Department of Occupational Safety and Health Malaysia)-compliant, meeting all Malaysian legal requirements for lifting equipment. The process includes design validation, safety inspections, and official registration, all of which are managed as part of our standard delivery.

By adhering to these standards, we ensure that every overhead crane delivers safe and reliable operation across all industrial applications.

Is crane servicing and maintenance provided?

Yes, we provide comprehensive servicing and maintenance for all crane and hoist systems.

Standard Coverage Includes:

✔ 1-Year Warranty – Full coverage for crane & hoist systems.

✔ Free Workmanship & Inspection – Ensuring optimal performance post-installation.

✔ Routine Maintenance – Safety checks, component testing, calibration, lubrication, and performance optimization.

✔ Repair Services – Prompt troubleshooting and fixes to minimize downtime.

Optional Crane Care Package (Extended Support):

🔧 Periodic Maintenance – Scheduled servicing to prevent failures.

⚡ Unlimited Breakdown Support – Priority response for emergencies.

🔄 Parts Replacement – Wear-and-tear components included.

📜 JKKP/DOSH Compliance – Assistance with certification renewals and inspections.